Ubiquitous ID Center Activities

At the Ubiquitous ID Center, we are engaging in food product verification trials with an eye toward the verification of ucodes, RFIDs, etc., and the expansion of application examples.

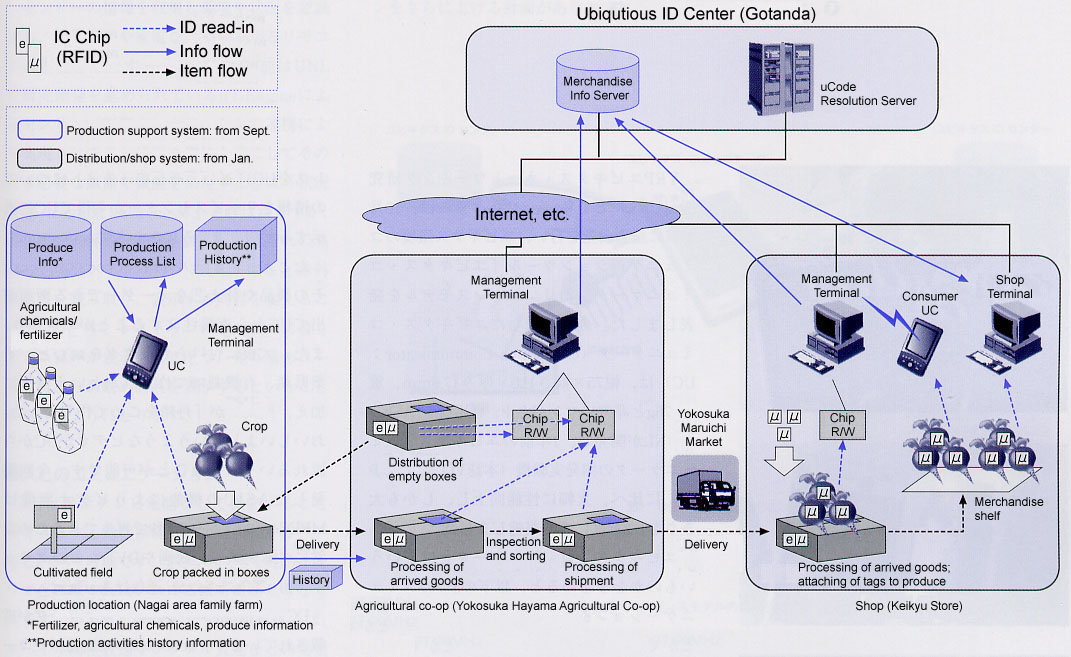

These matters were selected for the 2003 General Food Product Measures Project - Traceability System Development Project, which made the T-Engine Forum the main body for executing them, and which is proceeding through cooperation obtained from the Yokosuka Hayama Agricultural Co-operative (production location), K.K. Keikyuu Sutoa [Keikyu Store supermarket chain] (sales shop), Yokosuka Seikabutsu K.K. [Yokosuka green grocery] (distribution), etc.

We began test preparations for system construction, etc., from July 2003, then we planned a trials schedule of a production support system at a production family farm from the end of September of the same year, and trials of a distribution utilization system in the distribution process and shops from January 2004.

The main objectives of the verification trials is as follows:

First, develop a system that integrates a system that checks for work errors and operations errors in production and distribution with a system that traces, and, by means of this, aim at a situation in which all the players concerned with the traceability chain can directly received the benefits of this system. In the trials on this occasion, it has been our thinking to concentrate on the check functions in the production stage in particular.

Second, we have made as an objective verifying the usefulness of a food traceability system that uses an integrated ubiquitous environment system in which the most leading edge, ultra-small RFID and ucode technologies are utilized.

To start with, in regard to the first objective, in order to carry out food product safety and trace the causes and specify the extent of damage following some sort of accident, it is necessary for the circumstances of food product handling in all the stages of production, distribution, and shops to be recorded so that it is possible to do tracing afterwards. Nevertheless, in the current traceability approach, as the benefits to the ultimate consumer are maximized, the cost of participation to the producer conversely becomes a burden, and thus an incentive temperature gap has appeared. However, in order to have total tracing, the participation of producers is indispensable, and thus how to raise the merits for the producer becomes the key to spreading and driving forward traceability. In the system in these verification trials, we have made as an objective establishing a traceability system structure that is profitable even to the producer, and we have tried out the following measures.

|

|

Checking and tracing of the production processes at the family farm using RFIDs and a handheld terminal |

| We record using RFIDs and a handheld terminal at the time of spreading, when, what type of agricultural chemicals, and how much were spread. Also, we support quality ensuring in the production processes by comparing the production work circumstances at the family farm with the "Standard Production Procedures" that the agricultural co-op has made as the standard for quality management, and feeding back the information to the family farm. | |

|

|

Following distribution, making public in the shop the trace information from the production processes |

| When we pass over the top of an RFID that has been attached to a food product in the distribution stage a handheld terminal that has been placed in the shop, it is possible for us to confirm its production and distribution circumstances and the circumstances of agricultural chemical administration. | |

|

|

Making public via the Internet basic materials data that record the relationship of production methods and safety |

| We make public via the Internet the basic materials that serve as ingredients to judge the safety of the food products that you yourself are eating. |

Herein is the part that serves as the forte of this research and development. At the same time we record the production processes at the family farm and compare and check them with the standard production procedures, we automatically check in that spot also as to whether the method of spreading agricultural chemicals, etc., is correct, and if there is a problem, we join it with a system that warns the worker. By means of this, a positive merit by means of which this trace system will be introduced arises for the producer also. If, based on this checking, we succeed in ensuring agricultural product quality and in decreasing mistakes in production processes, such as in the spreading of agricultural chemicals, it comes about that we can also decrease feelings of resistance on the side of the producer toward making public information from the production stage--specifically, a check on the amount and period for the fertilizer; a check on the combination of agricultural chemicals; a check on dilution density; a comparison with past spreading history; a check of environmental conditions, such as temperature and humidity, a check on the limitations of the agricultural chemicals to be spread; a check in regard to influences on nature, such as rivers, etc. By automatically checking these many, complicated production management conditions simultaneously with a trace (records), we also carry out production support for the producer.

Next is the second objective, which is verification of the usefulness of utilizing the most leading edge, ultra-small RFID and ucode technologies in food traceability. As for the RFIDs in these trials, which assume pasting onto products, the chip size is 0.4 mm square, and even if we take into consideration the antenna for non-contact communications, because it is on the order of 2 mm wide and 5 mm long (about the size of a toothpick), it is possible to attach it to various types of food products. Also, even for the device for recording information onto and reading from the chip, by means of using a a handheld device (a Ubiquitous Communicator) in the shape of of a PDA, we construct an easy-to-use system for the workers in production, distribution, and shop locations.

The system configuration in the present verification trials is as in Fig. 1.

|

|

|

These verification trials began the work of acquiring product trace information by obtaining the cooperation of a test cooperation family farm (a JA Yokosuka Hayama association member) from September 2003. The products that serve as the objects of the trials center on daikon and cabbages, which are designated products in the Yokosuka Hayama district. This summer, which was a cold summer record wise, the test cooperation family farm participated in a Ubiquitous Communicator operation explanatory meeting while they were extremely busy with soil preparation and seed sowing, and having mastered the trace operations for production activities, they are putting it to use in their daily farm work. If the weather is good hereafter, for about one month from the beginning of the year, RFIDs assigned with ucodes will be put on green neck daikon and early spring cabbages that boast the greatest number of shipments in the East Japan region, and then they will be put on display at Keikyu Store counters. In the Keikyu Store chain that will serve as the outlet for the trials, we are planning the marketing of verification trials merchandise at three shops in Tokyo and Kanagawa, and in these shops we will create a special corner where an RFID reader terminal and a display for displaying merchandise information will be set up. In addition, we are also planning to distribute ucode reader equipment (the latest Ubiquitous Communicator) to specially selected customers, which will make it possible for them to reference information about merchandise they have purchased even at home. It would be nice if my readers also by all means dropped by one of these shops.

____________________

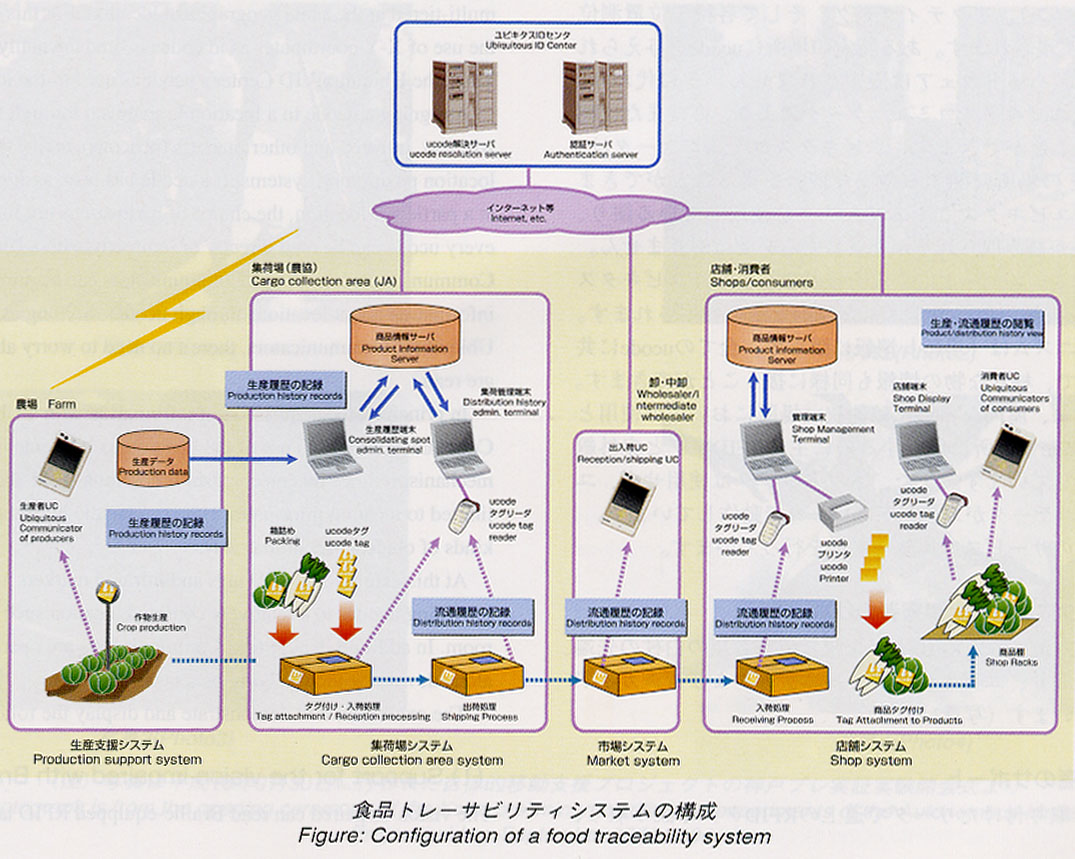

The following diagram, which shows an improved version of the above traceability system, is not part of the original article in Vol. 84 of TRONWARE. It appeared on page 31 of TRON SHOW 2005 Program & Exhibits Guide.

|

The above article on T-Engine appeared on pages 58-59 in Vol. 84 of TRONWARE . It was translated and loaded onto this Web page with the permission of Personal Media Corporation.

Copyright © 2003 Personal Media Corporation

Copyright © 2003 Sakamura Laboratory, University Museum, University of Tokyo